Microcab has extensive experience in the development of prototype fuel cell electric vehicles (FCEV) and have engaged with partners in industry, supply chain and academia resulting in an extensive hydrogen and fuel cell network. Our FCEVs have been designed and built from the ground up, and have road legal status, and have been demonstrated in many locations.

Hydrogen and fuel cell powertrains also offer the potential to reduce emissions in the aerospace sector. Airports and aerodromes have contained areas and specific duty cycles, which are ideal for installing hydrogen refuelling facilities. These can be used to refuel light and medium aircraft, as well as FCEV ground support vehicles.

AUTOMOTIVE

H2EV: THE MOST EFFICIENT CAR IN THE WORLD?

The original H2EV platform was an exercise in minimalism, designed for maximum efficiency and, of course, zero emissions at tailpipe. Drawing on lean weight principles developed in Formula 1, the bespoke Lotus built chassis is a flexible design and adaptable to van, taxi, or compact car. Probably, still the most efficient car in the world!

Case Study: Mahle MEET Project

In 2017 we built LHD demo vehicles for German Tier 1 company Mahle Powertrain, to support their Mahle MEET (MAHLE Efficient Electric Transport) project. These unique, vehicles were showcased by Mahle at the IAA show in Frankfurt and this commercial project included joint development of a new interior for the H2EV, which is now fully integrated into our own Vianova platform.

Vianova: Plug Fuel Cell Technology

In 2020, further upgrades on the H2EV platform resulted in the Vianova. Retaining the original specification which meets the Royal Mail light van payload volume of 1 cubic metre, the hybrid plug fuel cell minimises the battery pack weight and has a range of up to 175 miles on hydrogen, with a further 60 mile range from battery pack.

The Vianova features new composite materials developed in ECOBULK an EU funded Circular Economy project. Click here to learn more.

VIANOVA PLUS: ZERO EMISSION DELIVERY VANS

The Covid pandemic coupled with the rise in online shopping

has increased home deliveries highlighted the need for zero emissions delivery vans. We developed concept designs for a new FCEV platform for a 2.5-ton van and our NVN funded report sets out a technical blueprint to retrofit polluting vehicles within a Circular Economy business model which extends the life of existing vehicles and components. Report available on request.

AVIATION

Aviation and hydrogen

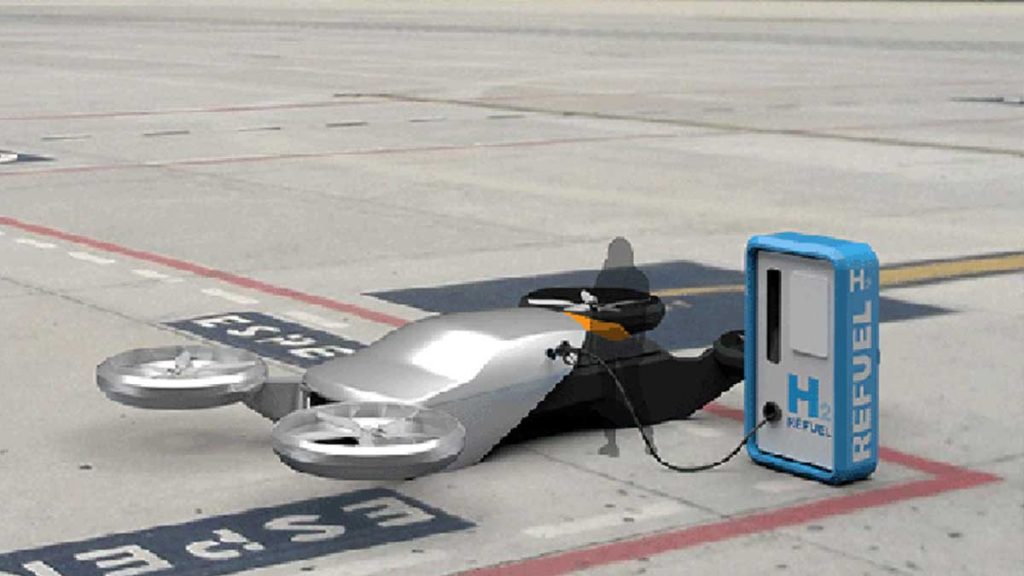

Hydrogen fuel cell powertrains are key to a sustainable aviation future. New aircraft types with hybrid fuel cell electric powertrains are coming to market. They have the capability to reduce the emissions of light aircraft, as well as ground-based support vehicles. Defined areas of operation (both airside and ground side) make ideal sites for hydrogen clusters to develop.

Airport Infrastructure

Hydrogen supply infrastructure at an airport can also be utilised by ground support vehicles which stay on site, such as baggage handling units and aircraft tugs, all serviced by onsite refuelling facilities.

ZERO EMISSIONS FLIGHT

Fuel cell technology presents exciting opportunities in aviation, and green hydrogen as a fuel can decarbonise a range of small and medium aircraft such as UAV’s (unmanned aerial vehicles) and VTOL’s (vertical take-off and landing), carrying passengers and freight.

We are currently providing help and support to Civil Aviation Authorities, and other agencies exploring how hydrogen can support the route to Net Zero.

How can we help?

We offer expertise in hydrogen and fuel cell powertrains and access to our mature supply chain network.

Our team can provide targeted support to aviation sector clients on bespoke hydrogen fuel cell aircraft development and retrofit projects.

Contact us to see how we can add value to your project.

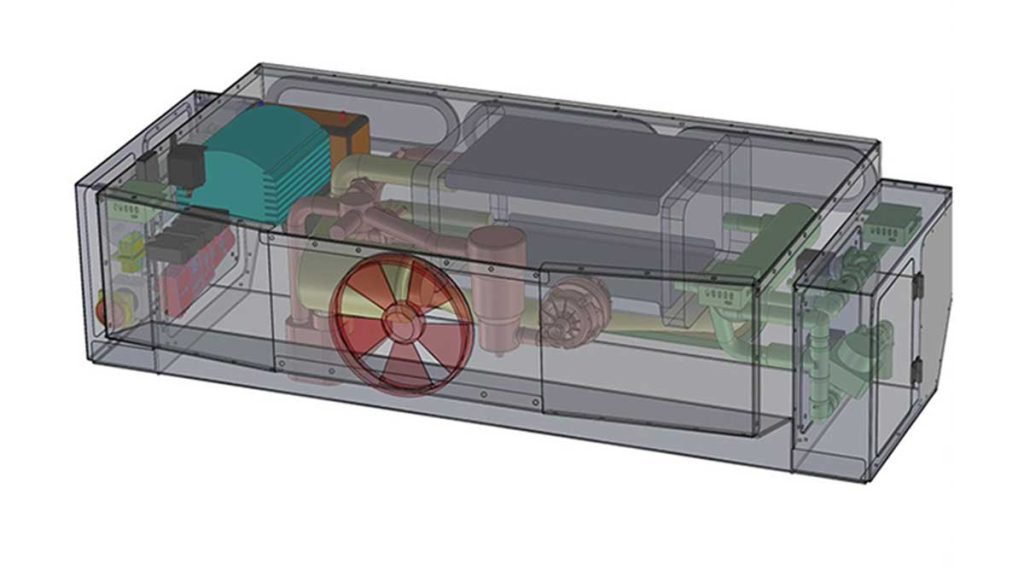

Pictured: Microcab’s integrated system design for a 10kW water cooled fuel cell.

WE WOULD LOVE TO HEAR FROM YOU

We are seeking collaborators, investors, end users, and manufacturing partners.