Our team has over 20 years of practical experience working with hydrogen and fuel cell technologies, enabling us to support businesses, organisations, academics and individuals who look to gain knowledge in the sector. Our commitment is to deliver new, clean technical solutions for a sustainable future and we support businesses to meet their Net Zero targets.

- We deliver technical reports on a range of hydrogen and fuel cell related topics.

- We provide design and engineering support with bespoke manufacturing of components.

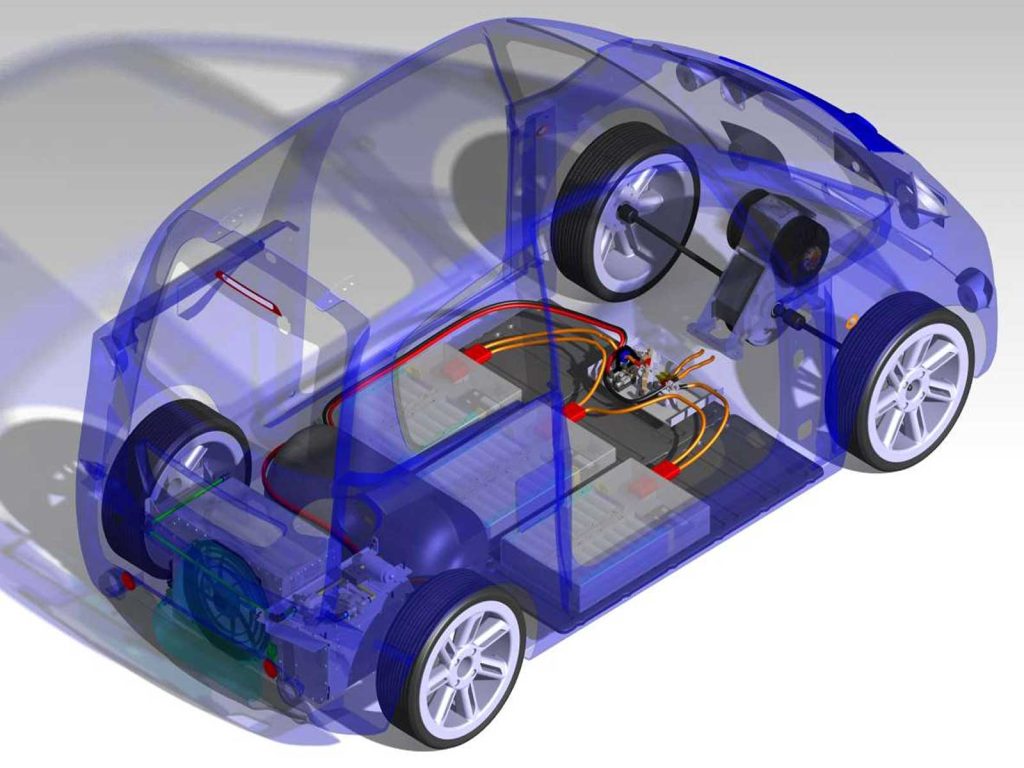

- We design hydrogen systems and fuel cell powertrain architecture.

- We offer a range of educational seminars and presentations.

Meet the Team

We are the tip of the Microcab iceberg, supported by our extensive network of freelance engineers and specialist sub contractors.

Commercial ProjectS

We work with our clients on a range of innovative projects.

A selection of case studies are highlighted here.

CASE STUDY

PROJECT: HYDROGEN SYSTEMS FOR LIGHT AIRCRAFT

CLIENT: CONFIDENTIAL

Our customer is developing a range of aircraft and are investigating the potential role of fuel cells and hydrogen in the powertrain. The project required a technical analysis of hydrogen storage systems and refuelling logistics. We provided insights for our customer in aspects such as codes and standards in the regulatory environment as well as a roundup of new developments in hydrogen technology. We were also able to provide details of components specification and procurement utilising our extensive supply chain network.

“The great piece of work Microcab did for us on hydrogen storage has been key in helping us set our strategy and move towards a prototype solution. It was comprehensive, detailed and delivered in a timely manner. ”

– Aviation company director

CASE STUDY

PROJECT: 2ND LIFE FOR FUEL CELLS

CLIENT: COVENTRY UNIVERSITY

UKMSN+ (UK Manufacturing Symbiosis Network plus)

The developing market for hydrogen fuel cell electric vehicles brings the opportunity to embed Circular Economy practices in the design, manufacture, use and end-of-life treatment of Fuel Cell vehicles, reducing demand for valuable finite resources. In a collaboration between Coventry University, Aston University, Microcab Industries and Oakdene Hollins, this research project applied an industrial symbiosis model to the critical supply chain of hydrogen fuel cells, seeking to develop a restorative business model utilising new data-driven approaches to monitor the health and usage of fuel cells.

“Microcab were a crucial partner in our project investigating the application of circular economy principles to hydrogen fuel cells. They provided expert advice on fuel cells, informing the development of new, data-driven approaches to fuel cell health monitoring and use. Microcab played an invaluable role in delivering the project outcomes and promoting the project to a wider audience.”

– Claire Brewis, Project Co-ordinator, Centre for Business in Society, Coventry University

CASE STUDY

PROJECT: THE ART OF CUTTING CARBON

CLIENT: THE EDEN PROJECT, CORNWALL

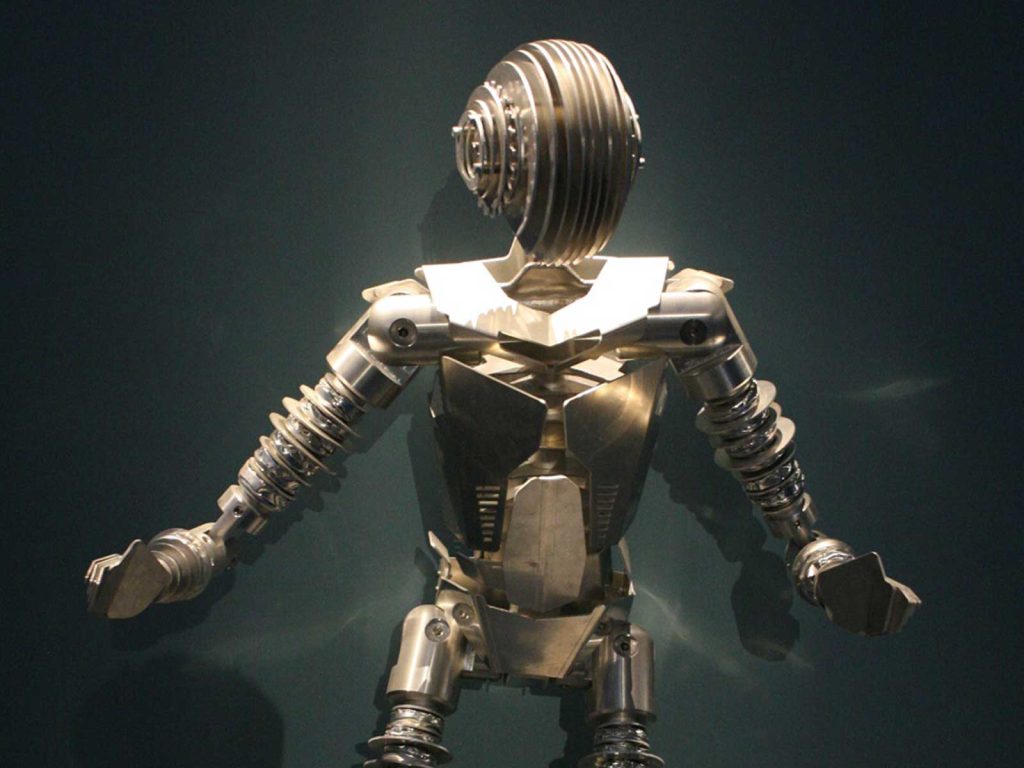

Microcab founder John Jostins was invited to submit designs for “Our Carbon Creatures” a joint project between the BBC and the Eden Project conceived by Roger Harrabin, BBC Environment Correspondent. This set of unique sculptures by four different artists, utilise the five most commonly used materials globally: steel, paper, concrete, aluminium and plastic.

“Call me Al” was designed and manufactured by Microcab, drawing on our experience of using aluminium structures within the Microcab H2EV and Vianova platforms. Our Carbon Creatures can be viewed in a permanent exhibition at the Eden project in Cornwall until 2025.

“I met John Jostins when he was an outstanding student at art school. Years later we re-met and I reported on his innovations through Microcab. John was a natural choice to provide a sculpture for my documentary and exhibition “The Art of Cutting Carbon” for the Eden project in Cornwall.”

– Roger Harrabin, Environmental consultant and ex BBC Environment Correspondent

CASE STUDY

PROJECT: HYDROGEN SAFETY

CLIENT: MAHLE POWERTRAIN LTD

As a Tier 1 automotive supplier, Mahle Powertrain are synonymous with quality engineering. We supported Mahle’s transition towards hydrogen fuel cell powertrains and technology with a series of seminars on hydrogen covering key topics such as hydrogen in the automotive environment, and an overview of automotive hydrogen regulations.

Funded Projects

The Microcab team has collaborated extensively and has successfully attracted over £2 million in funding to support R & D work around hydrogen and fuel cells and to advance their zero-emissions technology offering.

A small selection of the completed projects are highlighted here.

FUNDED PROJECT

PROJECT: ECOBULK (2017-2021)

PARTNERS: 27 PARTNERS ACROSS 11 EUROPEAN COUNTRIES

FUNDING: HORIZON 2020

This Circular Economy project researched the harvesting of municipal waste streams to form composites for use in architecture, furniture and automotive interiors. Microcab designed and manufactured new interior dashboard parts for the Vianova, using newly developed composite materials. The parts were then disassembled and remanufactured as part of a practical demonstration of the project’s objectives.

“I was lucky enough to work with the Microcab team on the ECOBULK project. Our focus was the automotive sector and the circular economy. Microcab were a pleasure to work with – innovative, experimental, and keen to share thinking, information and new concepts for products and business models. I look forward to working with John, Anne, and the team again.”

– Olivia Bertham, Director, ORB Sustainability Consulting Ltd

FUNDED PROJECT

PROJECT: HYSMART (2021)

PARTNERS: BRAMBLE ENERGY, LOOP TECHNOLOGY, HSSMI, UCL

FUNDING: AUTOMOTIVE TRANSFORMATION FUND (APC)

The feasibility study HySMART was driven by an urgent need for hydrogen fuel cell system producers and associated supply chains to drive down costs and offer fuel cell vehicles on a cost competitive basis. Microcab shared knowledge on the integration of fuel cells into the automotive environment to support Bramble Energy’s fuel cell development. Advanced robotics processes to enable scale up in the manufacture of hydrogen fuel cell stack products were also investigated.

WE WOULD LOVE TO HEAR FROM YOU

We are seeking collaborators, investors, end users, and manufacturing partners.